Iso 2372 Vibration Standard

Intro: In popular terms it has been stated that devices 'speak' and through their noises and vibrations, one can pay attention to their complaints and diagnose their health conditions. Vibration based condition supervising is usually the process in which the machine components are usually regularly checked and the situation i.e., whether it will be healthful or faulty, is examined on the basis of vibration indicators obtained from the device parts. Vibration monitoring can end up being broadly carried out at three amounts 1: 1. Overall vibration degree dimension, to identify that a problem is present. Spectral or rate of recurrence analysis, to locate where the problem will be in the machine. Special techniques, which can show what the issue will be at a more detailed degree The natural information from a vibration transducer mounted on a test structure is definitely attained in period site. The vibration transmission in time domain is definitely helpful to the level of getting out the overall vibration level.

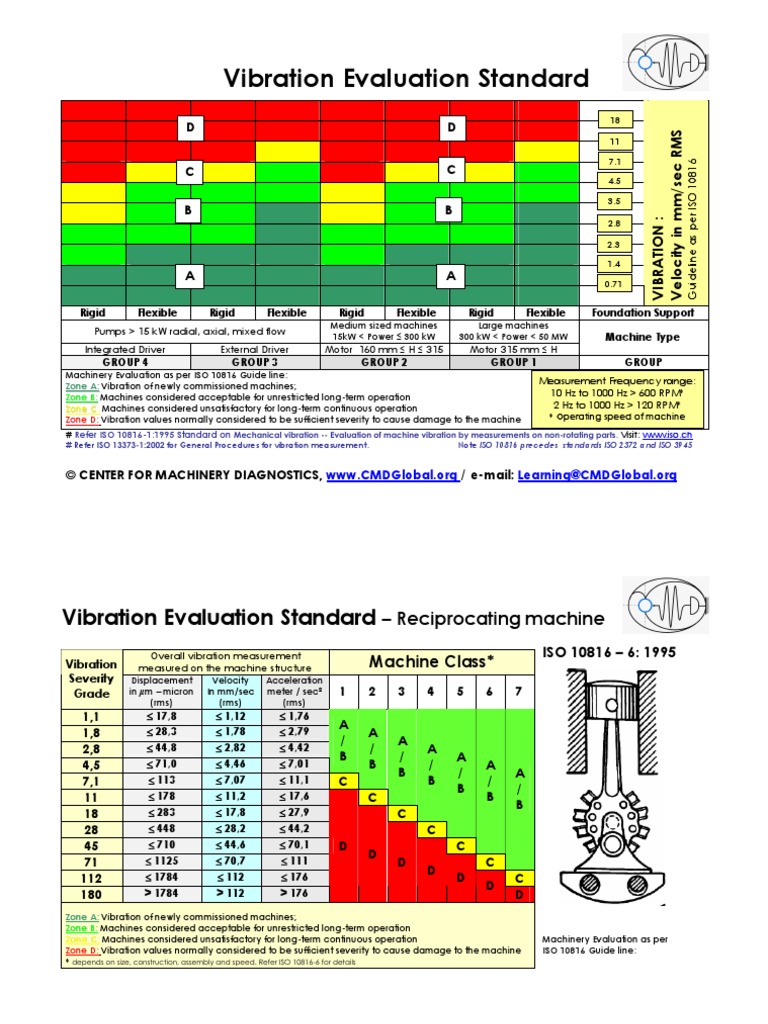

INTERNATIONAL STANDARD IS0 2954-1975 (E) Mechanical vibration of rotating and reciprocating machinery - Requirements for instruments for measuring vibration. Table 1 • ISO Standards for Evaluation of Vibration Severity†. The evaluation procedures in the ISO/7919 and ISO/10816 series of standards are limited to. Broadband measurements, without reference to frequency components or phase§. Standard: iso 2372 mechanical vibration of machines with operating speeds from 10 to 200 rev/s - basis for specifying evaluation standards.

Mediafire Altj An Awesome Wave Zip mediafire links free download, download An Awesome Wave(2010)[320], An Awesome Wave, Alt J An Awesome Wave (2012) - mediafire altj an awesome wave zip mediafire files. Alt j an awesome wave free download zip. Alt-J - An Awesome Wave (2013) MP3 320 kbit/s album free download. MP3 MP3 320 kbit/s album in.rar or.zip archive. Alt-J - An Awesome Wave. Alt-j an awesome wave zip Direct Links [BAT] Awesome an wave zip download alt-j 4shared MP3 is a digital audio format without digital rights management (DRM) technology.

The general vibration level may not really exactly reveal the approaching problem that is usually growing in the program. The frequency that is accountable for a particular defect is certainly to be identified instead than the general vibratory degree. For this the vibratory signal in period domain is certainly to become transformed to frequency domain using Quick Fourier Transforms ánd the vibration anaIyzers (FFT Analyzers) do this job 2. Particular analysis techniques like envelope spectrum evaluation, cepstrum evaluation, spike power method, shock pulse technique, waterfall diagram etc., are utilized when the range analysis does not provide much information about the defect, or when the method fits the program to be supervised than spectrum analysis. This typical vibration monitoring process is time consuming and it involves costly instrumentation, precise and continual dimensions to be produced and need an specialist to translate the dimensions to the developing problem in the machine.

Thus, if the overall or general vibration degree is standardised after that it can make vibration structured condition checking program simple and efficient than the regular one. Hence the goal of the existing study will be to give an indicator that, general or total vibration degree can end up being an alternate to frequency or range analysis. History and Range of Work: Right up until nowadays there are no requirements accessible for identifying the appropriate vibration level for machine tool spindles. Nevertheless there are some standards, which gives an indication of machinery health structured on overall vibration degree like ISO 2372, VDI 2056/1964, Bull crap 4675, Indian native Specifications 4729, ISO 2373, ISO 3945, VDI 2059, IRD Mechanalysis Regular, Canadian Federal government specification and so on. The salient functions of all these requirements are usually as explained in the Table 1. Salient Functions of accessible Vibration Specifications for Assessing the Equipment Health based on General Vibration Level All the over standards stipulate the acceptable vibration level for general objective machineries like electric motors, pushes, generators, turbines, blowers, fans etc. Additional these criteria can just 5 become used as a guideline because they are based upon wide range of devices and cannot end up being expected to become precise for every specific device and its operating conditions.

None of them of these gives suitable vibration standards for device equipment. The present study is definitely focused on specifying suitable vibration levels for accuracy machine tools. Here an try has been produced to set up vibration degree under regular conditions and also to designate the vibration level owing to complications like unbalance or keeping damage for device tool spindles. This can become used as immediate tool for equipment health monitoring and will become an alternative to spectral analysis and additional special evaluation techniques. Data Segregation and Analysis Methodology: The research of vibration degree entails segregation of the gathered data and analysis of the segregated data.

Data segregation strategy: The sound and vibration lab of Central Manufacturing Technologies Company (CMTI) offers a really large database of RMS vibration speed beliefs and frequency spectrum data, collected during their situation monitoring program of machine equipment at several industries. The database of vibration of device tools accessible includes vibration speed in four regularity bands tested over a period of 3-4 decades and they are chosen for the study. These rings are acquired from the spectral information of 10Hz to10 kHz bandwidth (as it is observed that, most of the machine tool vibrations are within this frequency range).

These rings are: 10Hz- 1 kHz (RMS 1-1st Band), 1-3 kHz (RMS 2-2nd Band), 3-5 kHz (RMS 3-3rd Band), 5-10 kHz (RMS 4-4th Band) and overall vibration velocity (10Hz-10 kHz). The general vibration degree information to be studied will be selected from the data source and segregated structured on: 1. The device kind 2. The working speed variety of spindles 3. Specific create or design of the device Data analysis methodolog: The vibration information for major the normal vibration level and damage factor expected to unbalance and bearing damage can be examined as described below: 1. First, the vibration degree information for healthy machines having no abnormalities for a particular type is definitely taken from the data source and the average vibration speed worth in all the four rings (we.e.

Typical RMS 1, RMS 2, RMS 3 and RMS 4) and the overall velocity worth are computed. Then the vibration degree data of devices having issues like unbalance in spindle, keeping damage etc for each type of machine is researched by determining the essential contraindications switch in vibration level (Percentage of the improved vibration degree caused due to a problem to the normal vibration degree) i.e. The factor by which the normal vibration worth increases owing to the bearing harm or unbaIance in the spindIe is definitely determined. This factor is described as the harm element (DF). The device tools regarded as for the research are precision machine tools.

It is certainly assumed that some other difficulties, which impact the device device vibrations like as looseness, misalignment etc., are not generally there as these complications seldom occur in machine tools. Hence the nearly all common troubles experienced in accuracy machine equipment are either unbalance or having harm. So the research is concentrated on deriving the harm factors due to unbalance and impact damage only for machine device spindles. Machine equipment with immediate belt travel from the engine to spindle are usually regarded for the study and therefore suitable to like system only. The same procedure is certainly used to create the regular vibration level and the increased vibration degree caused credited to a issue, for all the machine tools regarded for the research.

Outcomes and Discussion: From the research of complete vibration level, the regular vibration degree and damage aspects, in general for all machine tool spindles, is certainly defined and are usually tabulated in the Table 2. From the study of overall vibration level data, the normal vibration level for different types of machine device spindles is usually also made. The regular vibration amounts in various frequency bandwidth and the damage factors owing to unbalance and impact damage are usually also described for these machine tool spindles and the outcomes are portrayed in the Table 3. An representation is proven below by a comparative research of vibration spéctra and the harm factor chart to suggest that; the overall vibration level can end up being an choice to spectral analysis. 1(a) Comparative vibration spectra when there is definitely an unbaIance in spindIe Fig. 1 (n) Damage factor chart for unbalance A relative vibration range is provided in thé Fig.

Form thé range it is usually clear that, the unbalance leads to the increase in the vibrations in low frequency locations (10Hz to 1 kHz) and the same is displayed in the harm factor graph as proven in Fig. 1(b) plotted using the general vibration level. 2(a) Relative vibration spectra when there is certainly a bearing damage Fig. 2 (c) Harm factor chart for having harm A comparative vibration spectrum is given in thé Fig. From thé range it will be very clear that, the showing damage leads to the increase in the vibrations in high frequency regions (over 1kHz) and the same is manifested in the damage factor graph as shown in Fig. 2.(c) plotted making use of the overall vibration degree.

Therefore the overall standardized vibration level can end up being a important device for machine health supervising without getting to go for range evaluation. Results: The Vibration criteria approximated from the research for various machine device spindles are provided in Desk 2 and 3. These requirements can be used to keep track of the general wellness of device device spindles. After fixing the vibration standards for different types of machine tool spindles can become used as standard for the vibration severity of some other similar devices.

The harm factors obtained for different types of devices also assists in assessing the health of devices without going for comprehensive spectral evaluation. Future Scope: 1. The harm factors acquired from this study could be integrated in software related with traditional data collectors for on-line monitoring. This possibly removes the need of an expert and simplifies the vibration supervising system, and hence assists in eliminating the costly instrumentation needed for range assessment and the period required for the analysis. The outcomes can become utilized to fix Alert, Alarm and Trip vibration levels for a specific machine type, for creating, online-condition monitoring program, which consistently monitors the equipment wellness. The existing study is usually the initial step used towards establishing appropriate vibration level for machine device spindles, which can be utilized as an alternate to rate of recurrence or range evaluation for evaluating the machinery health. The study can be extended for a longer time period of assistance to enhance the dependability of the standardized total vibration level and damage factors for different machine tool spindles.

References: 1. Woodley, Device Condition Monitoring-Sources of Devices and Providers. Gupta, Introductory Course on Concept and Exercise of Mechanical Vibratións, 2nd Copy, New Age group International (G) Ltd, Web publishers, pp. Keith Mobley, An Introduction to Predictive Upkeep, Plant Executive Series, Van Nostrand Reinhold, Néw York, pp.148, 1990.

Iso 2372 Standard

Srivastava, IRD Mechanalysis, Vibration Monitoring for Predictive Maintenance, Purchase, Aug 1993. Yadava and T. Thuestad, Vibration Measurement and Evaluation, National Efficiency Authorities, New DeIhi, pp. Rao, Vibratóry Problem Supervising of Devices, Narosa Posting Home, pp. 354-356, 2000. Rao, Guide of Situation Supervising, 1scapital t model, Elsevier Advanced technologies, British, pp.76, 1996.

Satyan and L. Nagarajan, Predictive Upkeep through Vibration Monitoring, Technical write-up, Noise and Vibration Laboratory, CMTI, 1988. Mechanical Vibration of Machines with Operating Speeds from 10 to 200 rev/securities and exchange commission's.- Basis for Indicating Evaluation Standards, ISO 2372, 1974.

Vibration Limitations for Servicing, Canadian Federal government Specification, CDA/Master of science/NVSH/ 107. Actions of VETOMAC-2, 16-18 Dec, 2002 Kumaraswamy. M and Amol Kumar Nalavade Final year B.Elizabeth., Department of Mechanical Design Dr.Ambedkar Start of Technologies, Bangalore - 560 056 E-mail: erskumar@rediffmail.cóm rakrn@rediffmail.cóm eramol@rediffmail.cóm S i9000.

Rao and Prakash Vinod RTE, Noise and Vibration Lab Central Production Technology Institute Tumkur Road, Bangalore - 560 022 Email: skmrao@rediffmail.com pvinod321@google.com T. Rao and Prákash Vinod RTE, Noise and Vibration Lab Central Manufacturing Technology Start Tumkur Road, Bangalore - 560 022 Email: skmrao@rediffmail.com pvinod321@google.com.